Marley Flow control offer a complete range of cooling tower products for every need as the SPX (Marley) agents in Eastern Australia & NZ, we represent the world’s only “full line” Cooling tower manufacturer - able to offer the complete range of cooling tower alternatives.

Marley Flow control offer a complete range of cooling tower products for every need as the SPX (Marley) agents in Eastern Australia & NZ, we represent the world’s only “full line” Cooling tower manufacturer - able to offer the complete range of cooling tower alternatives.

Our entire package tower range is avaliable factory assembled or we can build on site, ideally suited to roof top builds saving time and money.

Cross flow v Counter flow explained in this video

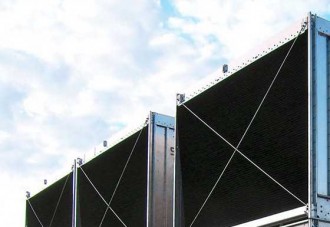

Cross flow cooling towers

Cross Flow cooling towers are evaproative towers with the air entering the tower over it's entire height with a large central plenum. The air travels across the waters path (cross Flow) then the warm moist air travels vertically up the plenum and through the fans to atmosphere.

Highest Single Cell Cooling Capacity*.

The NC offers the highest tonnage per cell and the highest ASHRAE 90.1 performance available – up to 2189 tons (9614 kW).

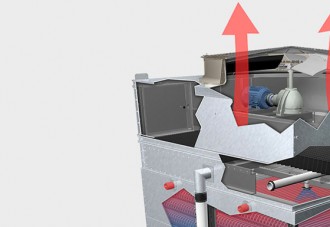

Counter Flow Cooling towers

Counter Flow cooling towers are evaporative coolers with the air inlet at the lower portion of the tower and fill pack across the entire width of the tower, the air travels vertically against the path of the water (counter flow).

Aqua tower

One of the very first factory assembled evaporative cooling towers ever designed and manufactured. Evolutionary enhancements over more than 70 years have made this the cooling tower of choice for over 50,000 installations since 1947! The Aquatower cooling tower has inspired many imitators, but only Marley can offer you the original. Its compact size means there are no hidden spray systems, tiny nozzles, or enclosed basins. All primary components of the Aquatower cooling tower are open to view, which means that maintenance does not get any easier.

One of the very first factory assembled evaporative cooling towers ever designed and manufactured. Evolutionary enhancements over more than 70 years have made this the cooling tower of choice for over 50,000 installations since 1947! The Aquatower cooling tower has inspired many imitators, but only Marley can offer you the original. Its compact size means there are no hidden spray systems, tiny nozzles, or enclosed basins. All primary components of the Aquatower cooling tower are open to view, which means that maintenance does not get any easier.

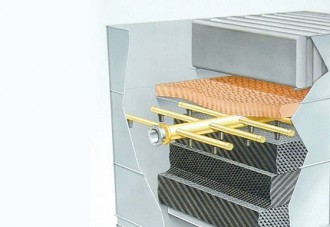

Evaporative Fluid Coolers

The MH Fluid Cooler remains one of the most efficient systems and best choices for industrial and HVAC closed-loop applications. By keeping the process fluid in a clean, closed loop, and combining the function of a cooling tower and heat exchanger into one system, the MH Fluid Cooler provides superior operational and maintenance benefits.

The MH Fluid Cooler remains one of the most efficient systems and best choices for industrial and HVAC closed-loop applications. By keeping the process fluid in a clean, closed loop, and combining the function of a cooling tower and heat exchanger into one system, the MH Fluid Cooler provides superior operational and maintenance benefits.

Hybrid Design

Utilizing a combination of fill media and prime surface coil(s), the MH Fluid Cooler offers significantly improved performance over conventional closed-circuit coolers.

Process fluid is pumped internally through the coil

Heat is transferred from the process fluid to the recirculating water as it flows over the outside of the coil tubes

The heated recirculating water is pumped from the collection basin to the gravity distribution basin

Evenly distributed over the fill media and coil, a small portion of the recirculating water is evaporated, efficiently rejecting heat to the atmosphere

Marley DT evaporative fluid cooler

The Marley DT Fluid Cooler is an induced-draft counterflow cooler. Its closed-circuit design keeps the process fluid in a clean closed loop. The fluid is cooled by recirculating water that flows over the outside of the heat transfer coils. Because the DT Fluid Cooler does not contain heat transfer fill media, it offers greater dry operation flexibility in cold weather than fill/coil hybrid coolers.

Evaporative condensors

Efficently condense refrigerants from hot gas to cool liquid in one operation.

Recold’s MC Evaporative Condenser utilizes the efficiency of evaporative cooling, along with the superior corrosion and heat transfer characteristics of copper to efficiently condense a given refrigerant from a hot gas into a cool liquid. Hot refrigerant vapor travels through the inside of the copper coil as cold water is sprayed over the exterior of the coil. Fresh air is pulled up over the exterior of the coil while cold water is sprayed down over the coil in an efficient countflow arrangement. Heat from the refrigerant is transferred to the spray water causing the refrigerant condenses from a gas to a liquid. Heat from the spray water is discharged through the atmosphere through evaporation of the spray water.

Plume abatement cooling towers

Plume from a cooling tower can pose several issues. It may affect visibility and safety as well as public perception. Plume abatement is the process of removing this visible plume.

ClearSky is a fully integrated system that operates more reliably than coil-based systems. By using a series of PVC heat exchanger modules in the tower plenum, ambient air condenses much of the moisture before it exits the tower thereby reducing the plume.

Forced draft cooling towers

Forced draft towers have fans that force the air through the cooling tower from the bottom, this style of cooling tower is often used insode buildings where the cooling towers are located in the basement or where sound abatement is required to meet strict noise constraints.

Forced draft towers come is fully evaporative towers, evaporative condensors of fluid coolers

Packaged cooling towers

We offer the biggest range of package cooling towers avaliable in the world. Pre-assembled here in New Zealand for New Zealand conditions we can supply all of our package towers ready for installation at your site. All models are cranable and transportable by truck.

-

CTI certified cooling towers

-

Field erected cooling towers

-

Timber cooling towers

-

Fiberglass cooling towers

-

Galvanised steel cooling towers

-

Stainless steel cooling towers

-

HVAC cooling towers